EURODECISION’s engineers, who are product design optimization experts, rely on a methodology that they implement rigorously in all their studies.

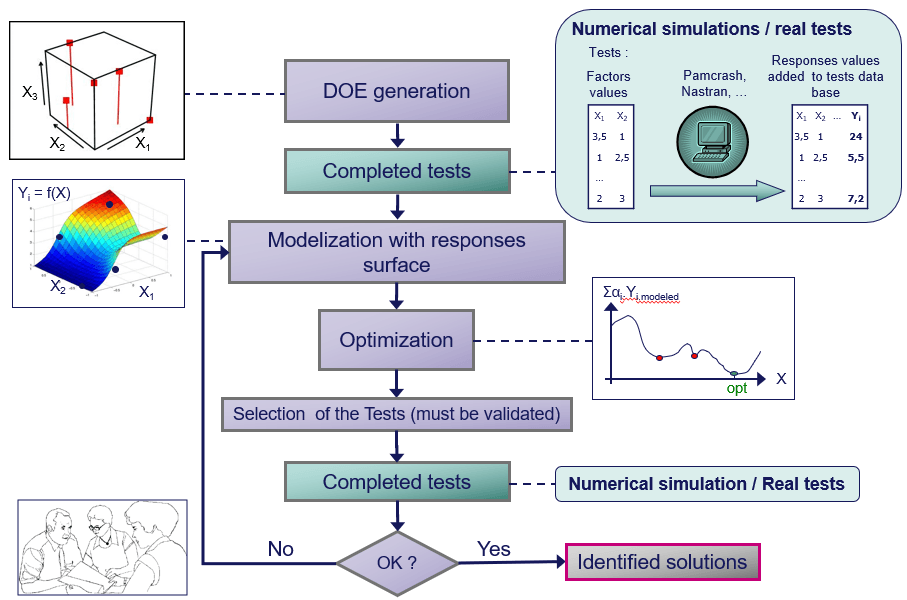

The purpose of product design optimization is to optimize the design or control processes of complex systems whose performances must be measured by simulators or real tests. Various kinds of simulators are suitable to perform numerical simulations of physical phenomena (such as finished elements) or event simulations. Their demand on computation resources can be high, so it is important to apply a research strategy that is economical with the number of evaluations it requires. Here is a block diagram of this methodology:

Product design optimization projects comprise the following stages:

Definition of the study scope

Clients set out the specifications describing their project goals, such as limiting pollutant emissions, achieving certain mechanical, thermal or aerodynamic performance levels, or reducing a product’s mass or volume. Then they list the design parameters such as parts thickness, parts shapes, the materials used, the presence or absence of a part, etc. and their range of variation factoring in technical constraints, including manufacturing constraints (demolding, weldability, etc.). In the proposed methodology, the parameters called “factors” are the design problem’s decision variables and the “responses” – mainly numerical simulation output data – are the criteria on which the specifications are based.

A design of experiments to kick off the study

EURODECISION generates the initial design of experiments to extract the maximum data based on a minimum number of simulations. Our engineers will be able to determine the influence of the factors and their interactions on each response in line with the specific structure of the chosen design. The responses obtained by simulating these first tests will enable them to construct response surfaces of these magnitudes in line with the factors. These models will give an approximation of the responses for a new test. These response surfaces, as opposed to the simulations, will be used in the optimization because they can be instantly computed.

Optimization on response surfaces and closure

The EURODECISION experts then use the response surfaces to generate optima using multi-objective optimization methods. Simulation validates these configurations that are supposedly optimal, and the real values are integrated into the test range. The response surfaces can then be reconstructed to improve their quality and look for new potential optima. This step is iterated until satisfactory solutions are obtained. The methodology generates solutions along the Pareto front presenting all the best compromises on the study’s many criteria. Thus, clients obtain numerical results that will support decision making.